Twin-roller Briquetting Machine

Power: 7.5-130kw

Capacity: 10-35TPH

Briquette Size: 30-60mm or customerized

Twin-roller briquetting machine is a kind of commonly used ball press equipment, and it has the features, such as high rate of balling, low energy consumption, compact structure, easy installation height and other obvious advantages, so it is welcomed by the masses of users and widely used in industrial production.

Speed regulating motor provides power for twin-roller ball press machine. The twin-roller ball press machine conveys the coupling to the main shaft through the pulley and the cylindrical gear reducer.

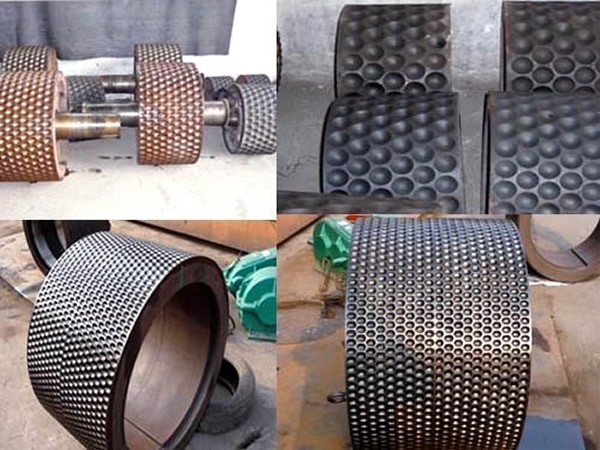

The driving shaft and driven shaft ensure synchronous operation through opening the gear. Rollers operate in the same direction and compress materials dropping from rollers. Each roller has a small pit on it, and materials are pressed into globular under the strong pressure.

The core part of the host is roller. When too much material or metal enters the space between two rollers, the hydraulic cylinder piston bears overload pressure, and the hydraulic machine will stop working to protect the roller from damage.