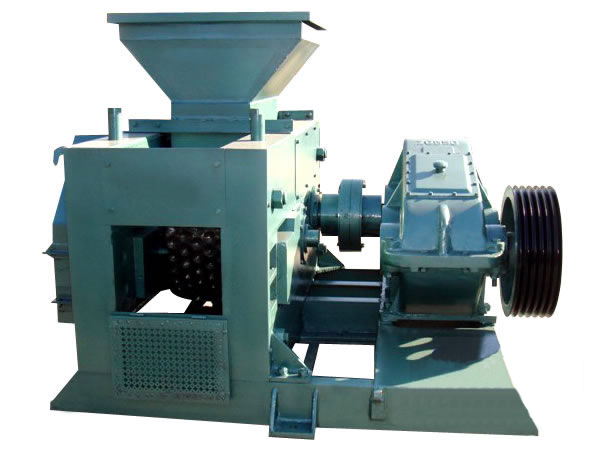

Coal Briquetting Machine

Power:7.5-30kw

Capacity:2-30TPH

Application: Coal briquetting machine is widely used in coal industry, metallurgy industry, chemical industry etc.

Coal briquetting machine plays a critical role in reusing powdery anthracite, soft coal, peat, coking coal and lignite for generating power, making gas, smelting metal, heating, etc. It is widely used in coal industry, metallurgy industry, chemical industry and other industries. Coal briquetting machine is divided into two kinds: briquetting with binder or without binder.

In addition, a great deal of enterprises in many countries such as China, India, Indonesia, Malaysia, South Africa, Nigeria, Kenya, etc. use this coal briquette making machine to produce coal briquettes used for gas making. In a word, the coal briquette processing equipment can help you maximize the value of coal resources.

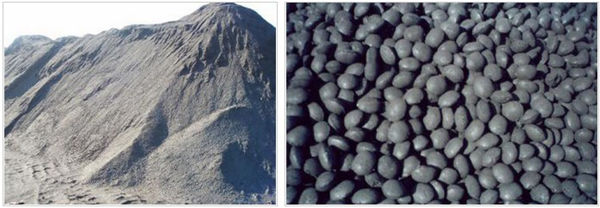

1. Get raw material prepared: sieving, pulverizing the charcoal lumps/chunks or coal mateirals into fine powder.

2. Get appropriate binder.

3. Mixing process: mixing coal / charcoal powder with binders and some other additives if needed.

4. Briquetting process/Extruding process: briquetting/extruding mixed charcoal powder into specific shape with charcoal making machine.

5. Drying process: sun drying or automated tunnel type continuous drying

6. Packing process: carton packing, gunny packing, paper packing.

Host gets power from the electromagnetic adjustable speed motor, and drives the driving shaft rotating by a reducer. The driving shaft and driven shaft keep synchronization operation. After the pressed material enter the feeding mouth, it is pressed into ball under great pressure. At the back of ball press machine, the hydraulic devices are installed, and it can protect the ball press machine from damaging when super hard material enters it.