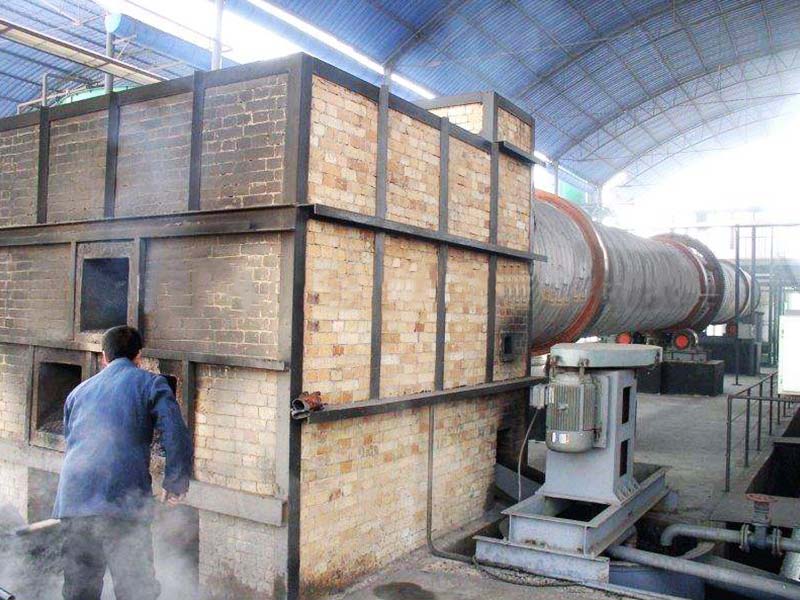

Hot-Blast Stove

Processing capacity: 1-2200t/h

Feeding size: 125-250mm

Processing material: barite, calcite, coal, concrete, cement, gypsum, limestone, granite, rock and so on.

Hot-blast stove is a machine supplying hot-blast air. The working process of a dryer machine needs a machine to supply heat source, and this is hot-blast stove. Hot-blast stove is steam dryer machine or airflow dryer to provide direct heat source, so that it plays an important role in the drying industry.

A hot-blast stove generally uses solid or liquid fuel such as coal, diesel oil or ethyl alcohol. After the fuel is burnt, high-temperature gas will be gained, and it will mix with the air to get gas with certain temperature which will directly contact the materials to be dried to make the water containing in the materials to evaporate, thus getting dry products.

Indirect type hot-blast stove is improved on the basis of direct type hot-blast stove, as some materials are not allowed to be polluted in the drying process or some materials are easy to react with hot air. Then using direct-contact heat source is not advisable, so that indirect type hot-blast stove needs heat exchanger and the bigger the size of the heat exchanger is, the higher the heat transformation efficiency will be.