NEWS&EVENTS

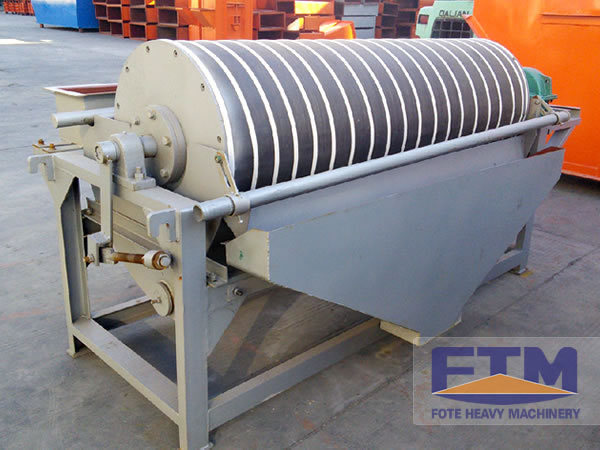

Drum wet magnetic separator's working clearance refers to the distance between the drum skin and the baseplate. It is where the ore pulp gets through. This clearance is exactly the effective area of magnetic field. Its thickness can be adjusted from 30 mm to 60 mm. No matter the working clearance is too big to too small, it will affect the separation index.

If the clearance is too big, the magnetic field force near the baseplate will be small. The mineral particles there are possible to flow into the tailings with ore pulp and thus the recovery rate will be reduced. Otherwise, if the distance is small, the recovery rate will become higher, but the concentrate grade will lower down. If the clearance is too small, the ore slurry will flow very fast in the working clearance, and some magnetic particles will be rushed into the tailings and results in a lower recovery rate.

The appropriate value of working clearance should be determined on the base of the specific production conditions in various factories. The concrete adjusting method is to add or subtract the gaskets on the four supporting points of the frame. Because the position of the drum is fixed, so when we add gaskets, the cell will be elevated and the working clearance will become smaller. When we subtract gaskets, the working clearance will become bigger correspondingly. The size of the working gap varies evenly along the axial direction. If the clearance is not the same at both ends, it will cause different flow rate of the ore slurry.

Working clearance can be measured precisely at the time of maintenance. We can put a piece of plasticene respectively on where the baseplate is close to the two ends, then fit on the cell, add enough gaskets and lay down the cell. Then we can take out the plasticene and measure out the thickness getting squashed. This thickness is exactly the accurate value of working clearance.