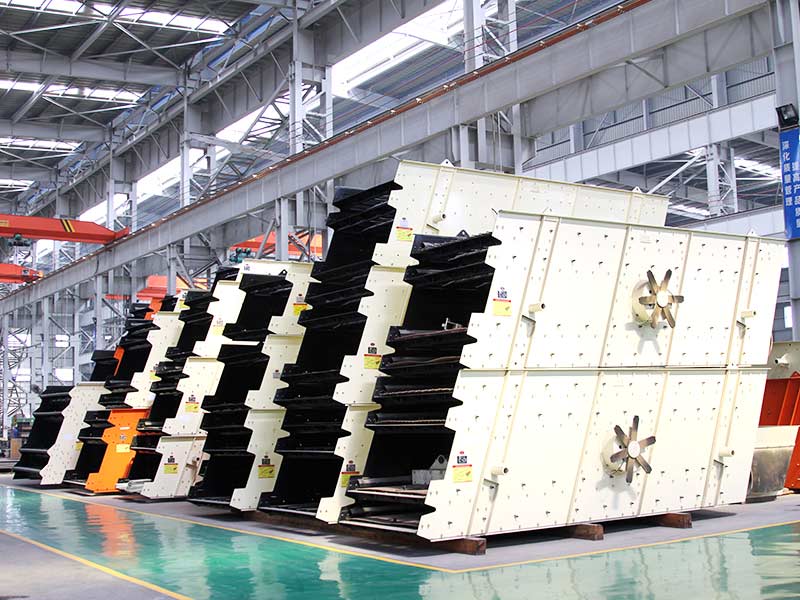

Vibrating Screen

Production: 8-800m³/h

Vibrating power: 800-970r/min

Application area:mine, building material, transportation, energy and chemistry.

Vibrating screen or vibratory screen is delicately designed for the screening operations in quarry plant. It can also be used for product classification in coal, ore dressing, building material, power and chemical industries. Fote vibration screen has advanced structure, strong exciting force, low vibration noise, easy repair, solid structure and long duration.

Fote Machinery can design various vibration screens with different vibrating modes and specifications according to the actual situation of different customers. The most commonly used vibrating screens are circular vibrating screen, sand vibrating screen and rotary vibrating screen.

Circular vibrating screen is a kind of multi-layer and high efficiency vibration screen. Circular vibrating screen adopts tube type eccentric shaft, vibration exciter and partial block to adjust the swing. Circular vibrating screen has long drip line and various screening specifications, which has the advantages of reliable structure, strong exciting force, high screening efficiency, low vibration noise, long duration and convenient repair. It is widely used in mining, metallurgy, coal, building materials, refractory materials, light industry, chemical industry, etc.

1.Stable vibration, reliable operation, long duration;

2.Simple structure, convenient replacement of screening sifter;

3.Low power consumption for per ton;

4.It can adjust the excitation force, control and change the flow at any time, which has convenient adjustment;

5.The vibration motor is the vibration source, which has low noise, low power consumption and simple structure;

6.Reliable operation, convenient installation and adjustment, light weight, small volume, convenient maintenance;

7.Due to the strong vibration of screening boxes, the blocking phenomenon of materials has been reduced, so that the screen has high screening efficiency and productivity.

| Model | Sieve area (㎡) | Processing capacity (m³/h) |

| 2YK1225 | 6 | 8-60 |

| 3YK1225 | 9 | 10-70 |

| 2YK1230 | 7.2 | 12-78 |

| 3YK1230 | 10.8 | 13-80 |

| 2YK1237 | 8.88 | 15-86 |

| 3YK1237 | 13.32 | 16-90 |

| 2YK1535 | 10.5 | 20-125 |

| 3YK1535 | 15.75 | 21-125 |

| 2YK1545 | 13.5 | 22-150 |

| 3YK1545 | 20.25 | 22-150 |

| 4YK1545 | 27 | 22-155 |

| 2YK1548 | 14.4 | 22.5-162 |

| 3YK1548 | 21.6 | 22.5-162 |

| 4YK1548 | 28.8 | 22.5-162 |

| 2YK1848 | 17.28 | 25-206 |

| 3YK1848 | 25.92 | 32-276 |

| 4YK1848 | 34.56 | 32-285 |

| 2YK1854 | 19.44 | 32-312 |

| 3YK1854 | 29.16 | 32-312 |

| 4YK1854 | 38.88 | 32-336 |

| 2YK2160 | 25.2 | 50-475 |

| 3YK2160 | 37.8 | 50-475 |

| 4YK2160 | 50.4 | 50-497 |

| 2YK2460 | 28.8 | 65-550 |

| 3YK2460 | 43.2 | 70-620 |

| 4YK2460 | 57.6 | 80-680 |

| 2YK2870 | 39.2 | 120-680 |

| 3YK2870 | 58.8 | 180-720 |

| 2YK3072 | 43.2 | 200-700 |

| 3YK3072 | 64.8 | 230-800 |