NEWS&EVENTS

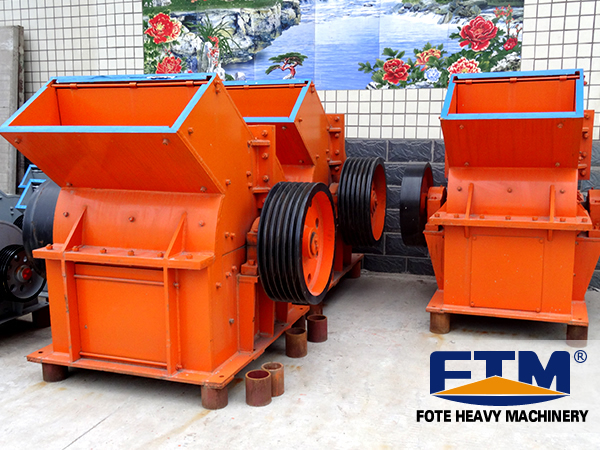

As the secondary crushing equipment, hammer crusher that has advantages of high crushing rate and production capacity is widely used in the mining, highway, construction, water conservancy project and other fields.

The most specific and professional equipment maintain methods put forward by Fote Machinery will help customers improve their comprehensive economic benefits.

1. Seriously control the material feeding granularity according to the hammer crusher technical parameters. Avoid materials exceeding maximum limited feeding granularity in the crushing cavity.

2. Forcing to start is unwarrantable when the equipment abruptly halts. At that time, you need check the hail reason, clear the materials in the crusher and then make a rebooting.

3. When abnormal noise exists, you need make a shutdown inspection. Inspection in the running process is not allowed.

4. After the crushing work, it is necessary to make a careful inspection to the wear pattern of hammer and lining plate. Regular maintain and change is needed according to the specific running statue.

5. Do not forget to inspect whether the gap between hammer and grate satisfies the equipment running demand. If there is any abnormal condition, please make a quick adjustment.

6. Clear the accumulated materials in the crushing cavity at regular intervals in case of damage caused by crusher component abrasion.

Hoping precautions of how to extend the service life of hammer crusher above-mentioned will help you and save your investment costs. Hammer crusher in Fote Machinery has affordable price and perfect using effect. Welcome to choose Fote Machinery.